Find your Valve replacement

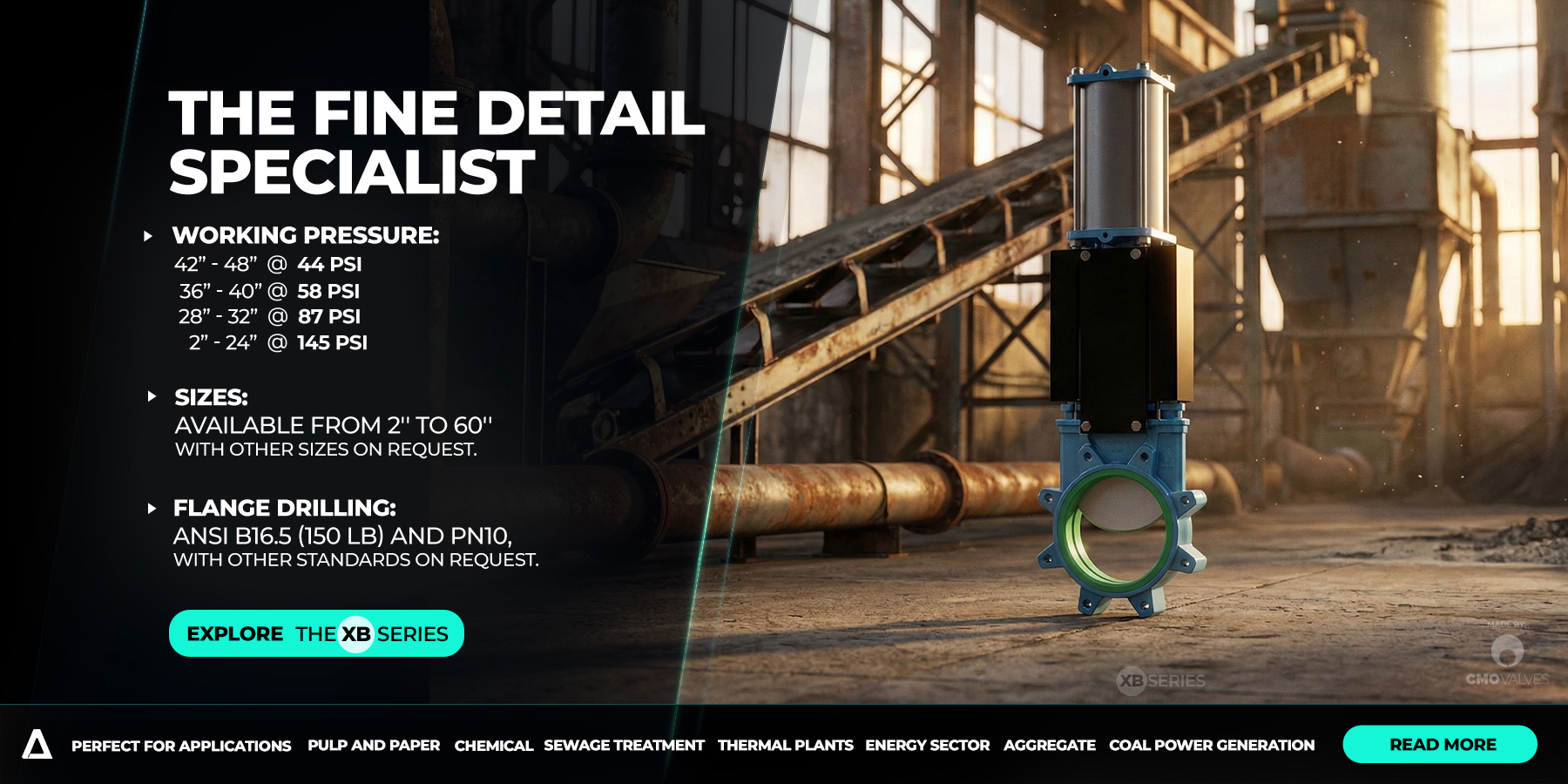

Model XB

XB liner tolerates alkali slurry at 150 psi and 185 °F. Crews replace the complete valve during a planned shift, gaining a fresh polyurethane liner and ready-to-run sealing surfaces.

Model GA

GA covers 2–54 in at 150 psi and 248 °F. Blade support design improves alignment in sanitary lines. Limit switches attach on the yoke, so automation setup is straightforward.

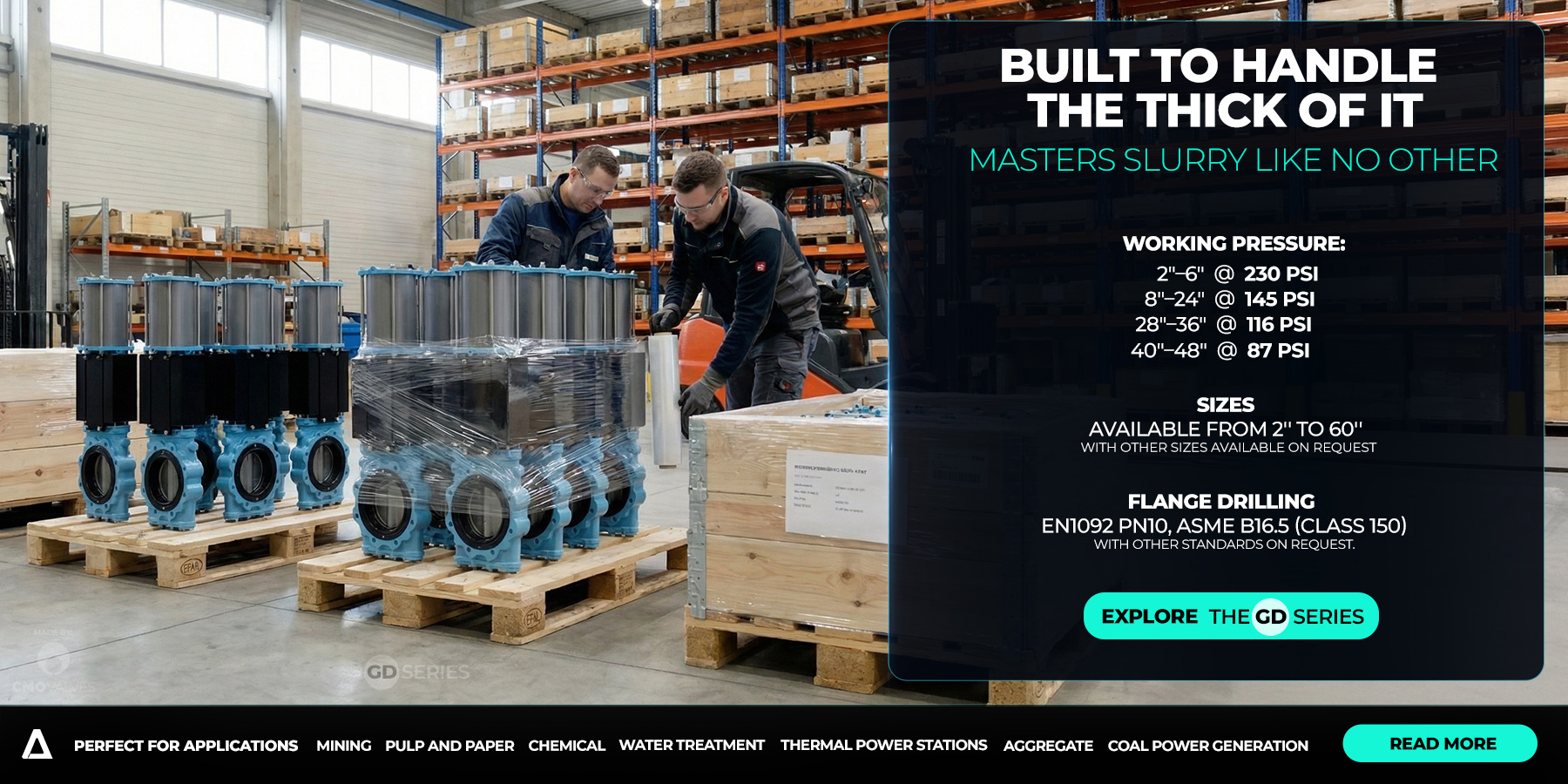

Model GD

GD keeps 150 psi at 248 °F EPDM service. FDA-grade coating is standard for water treatment. Adjustable seat screws let technicians refresh tight shutoff, extending valve service life.

Model GH

GH maintains 300 psi at 482 °F and features dual packing that trims stem torque. Pneumatic or electric drives arrive pre-mounted from Arnett, giving faster delivery to power projects.

Model GA

GA retains the 150 psi at 248 °F rating, provides a wide port that lowers pressure loss and fits pulp or wastewater lines. Weight is lighter than the original valve, and each GA size accepts one seal kit family.

Model GD

GD bolts to the same pattern, keeps 150 psi at 248 °F and uses an EPDM seat proven in abrasive pulp. Stainless or ductile-iron body choices match site specs, while a common GD spare kit simplifies storeroom planning.

Model GH

GH supplies a metal + soft seal rated 300 psi at 482 °F, ideal for hot mineral slurry or steam loops. Stainless body is stocked, and GH shares gland parts with GD, which trims spare inventory.

Model XB

XB handles 150 psi at 185 °F, featuring a polyurethane liner approved for hard-rock slurry. Planned replacement of the valve body at wear limit keeps maintenance predictable and process uptime strong.

Model GD

GD preserves 300 psi at 482 °F and uses hardened guide bushings that steady the blade in chemical duty. EN 10204 3.1 material certificates accompany each shipment for QA teams.

Model GA

GA meets the 90 psi light-slurry duty using the same face-to-face. GA, GD and GH share elastomer seals, which reduces spare parts in clarification loops to one shelf item.

Model GD

GD matches 150 psi at 248 °F and stainless slide rails steady the blade in thick pulp. Gland hardware equals GH parts, so mills keep one common service kit on hand.

Model XB

XB runs 150 psi at 185 °F. Valve body exchanges on existing studs, and the actuator re-attaches using the original yoke height, so field re-alignment is quick and accurate.

Model T

T retains 150 psi at 248 °F and uni-flow design. Cast-in bosses accept limit switches, letting water plants wire feedback quickly while stocking one seal kit for all T sizes.

Model XB

XB equals 150 psi at 185 °F and offers a molded polyurethane liner that deals with abrasive slurry. Valve replacement is fast, and stocking complete XB assemblies keeps site logistics simple.

Model GH

GH meets 300 psi at 482 °F. Chrome-plated guides lower blade torque in abrasive circuits. ISO 5211 pad receives existing actuators directly, so wiring and controls remain unchanged.

Model GD

GD matches 150 psi at 248 °F, maintains dual-flow sealing and ships in stainless if required. Same face-to-face length permits a swift swap during shutdown, and one GD service pack covers every size.

Model GA

GA holds 150 psi at 248 °F and includes a cast-in position indicator that helps audits in food or water plants. Elastomer seat and epoxy ductile body resist mild chemicals.

Model GD

GD equals 150 psi at 248 °F and mounts to an ISO 5211 pad, easing future actuation. Stainless trim handles bleaching liquor, and spare seals duplicate those used in GH.

Model GH

GH matches 300 psi at 482 °F. Chrome-nitride blade finish resists fly-ash wear. Existing controls stay as face-to-face and stroke length are identical, securing project schedules.

Model GD

GD carries 300 psi at 482 °F and presents live-load packing that keeps gland compression through thermal shifts. Chemical sites receive full 3.1 documentation for every order.

Model T

T keeps the 392 °F rating and introduces self-locking stem nuts that ease inspection cycles in steel-mill cooling water. Nickel-plated trim appears in the standard price list.

Model GH

GH maintains EPDM seal at 482 °F. PTFE guide sleeves lower stem torque, which supports long service on mine hydraulic cylinders. Bolt pattern reflects the HD valve, enabling fast swap.

Model T

T holds 150 psi at 392 °F with a metal seat. Nickel-plated ductile body matches clinker dust duty in cement mills, and actuators bolt on the ISO pad already cast into the bonnet.

Didnt find your actual valve for Arnett replacement? Ask Arnett Engineers by filling out the contact form below.

Find your Pump replacement

50 LH-PHO or 75 LH-PHO

Three-leg stand height equals ABS frame, thus sump floor bolts stay. Stainless lift chain eye accepts the original hook.

50 LH-PHO or 75 LH-PHO

Cable grommet and float switch entry are positioned to mirror Barnes layout, easing rewiring. Stainless hardware stands up to lime grit common in small pits.

150 LH-PBO or 200 LH-PBO

Hydraulic or electric Dragflow versions both match the discharge flange. If the site keeps an EL-H power pack, the motor envelope check ensures the hose routing stays clear.

50 LH-PHO

CD4MCu kit resists chloride-rich seafood wash water better than 403SS. Rail bracket supplied in 316, which meets the current corrosion audit. (Note: Just changed from 304SS to 403SS)

75 LH-PBO to 200 LH-PBO

Internal slurry seal permits dry run, so plant retires the external flush loop. Hi-chrome wet end equals 60 HRC Hard-Iron and flange pitch matches Flygt guide shoe which keeps rail hardware in place.

100 LH-PHO

Victaulic-style 6 in discharge supplied, so pit piping remains intact. Hi-chrome impeller adds two points on abrasion index which delays wear part changeout.

50 LH-PBO to 150 LH-PBO

TBM dry starts thanks to air purge built into the seal cavity, no surface air valve needed. The seal swap takes thirty minutes, as the cartridge design lifts clear of the wet end.

75 MH-PBO to 200 MH-PBO

TBM weighs about fifteen percent less yet shares the Hevvy rail bracket slot. Chrome-iron parts resist 60 HRC slurry and the motor is CSA Class I Div 2 capable at request.

100 MH-PHO

Explosion proof motor option keeps parity with WD3-XP spec. Footprint matches sump plate, so facility only reconnects power and level floats.

100 MH-PVO to 200 MH-PVO

TBM option in CD4MCu offers identical pitting index to duplex steel. Modular shredder nose fits the same frame which lets crews switch from open suction to cutter when ore changes.

100 LH-PBO

TBM motor fits existing bail spacing at the Cilantro mine site. Chrome iron wet end handles high SG slurry which raised bearing life in trials.

75 LH-PHO

Adapter plate supplied for 1960 era rail sets. Operators gain sealed bearings and chrome iron internals which lift mean time between pulls.

Size-for-size LH

The Mody Townley MSP is a cheap knockoff copy of the Polaris TBM. Discharge flange and rail lug match exactly, so only the motor lead is re-terminated. Shared wet end with TBM gives ready access to premium OEM chrome iron parts.

150 LH-PHO or 200 LH-PHO

North-American casting with 650 BHN chrome upgrades wear life over imported iron. Suction bell OD aligns, so dredge hose remains.

50 LH-PBO to 150 LH-PBO

Duty curve overlays Sulzer range. Built-in agitator uses motor torque, so no gearmotor is needed. Lifting bail spacing copies the XJ which keeps existing gantry hooks in service.

150 LH-PBO

Polyurethane coated suction cover option protects against phosphate sand. Bolt circle aligns with Pit Boss flange so crane change is rapid.

50 LH-PHO to 100 LH-PBO

Strainer height equals Tsurumi so solids path stays free. TBM agitator lifts settled sand which lets crews skip separate jet ring.

100 LH-PBO to 250 LH-PVO

PVO shredder kit matches MHW cutter profile and lifts solids capacity by about twenty percent. Discharge OD and bolt circle align, so crane swap completes inside a single shift.

Didnt find your actual valve for Arnett replacement? Ask Arnett Engineers by filling out the contact form below.